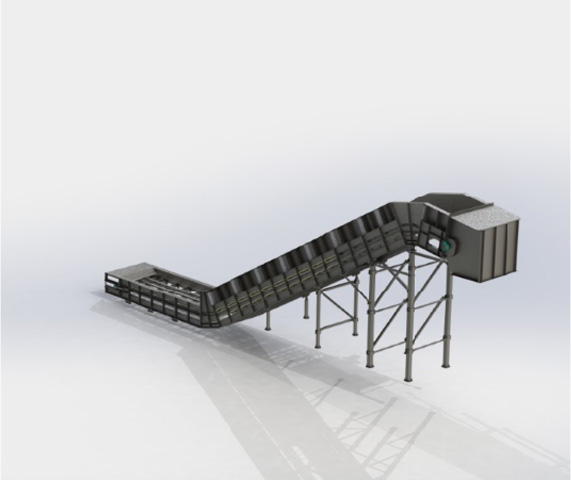

Slider Bed Transfer Conveyors

At Karl Schmidt Mfg Inc., we make some of the strongest and most efficient slider bed transfer conveyors available on the market. Whether you need to transfer, sort, separate, or load MSW, fiber, C&D, commingles, and recyclable mixtures, our slider bed transfer conveyors have what it takes to help you get the job done, quickly and efficiently.

- All of our standard slider bed conveyors ship with two emergency stop buttons, as well as protective guards that can be installed up to 8 feet above the ground.

- Our slider belt conveyors are manufactured to operate at a nominal speed of 40 feet per minute, unless otherwise noted at the time of shipping.

- The lead time of each slider bed conveyor system will depend on the current workload being enforced.

- Our slider bed conveyor systems are finished with one coat of KS Mfg blue industrial enamel to a minimum of 2 ½ mils DFT. Other colors are available upon request at the time of your order.

- All slider bed conveyors are equipped with a shaft-mounted inverter rated motor and gear reducer.

- All conveyor systems come with adjustable supports.

- Our conveyor system drive motors are TEFC rated 230/460 volts, 3 phase, and 60 Hz. Our systems feature reducers that are helical bevel shafts mounted with torque stabilizer arms.

- All metal surfaces are prepped with an SSPC-SP3 minimum, and all welding procedures follow the AWS section D1.1 guidelines.

General Information

Sizes

At Karl Schmidt Mfg Inc., we custom manufacture each slider belt transfer conveyor to meet the needs specific to each individual operation. Conveyor system size can be discussed when the order is submitted.

Frame

All slider bed transfer conveyors are built using formed sheet steel between the thicknesses of 10 gauge and ¼”. The frame of the conveyor system is cross-braced and welded to ensure stability. Additionally, our conveyor systems are mounted with lifting lugs — ensuring that it can be installed with the greatest ease possible.

Belt

All of our slider bed conveyor system belts are standard high-abrasion resistant belting, unless otherwise specified at the time of the order. Additionally, 2-ply flat belts and linings are manufactured with high-tension synthetic fabrics to reduce the likelihood of mildew and rot.

Contact Us To Discuss Your New Slider Bed Transfer Conveyor

Karl Schmidt Mfg Inc. is your trusted source of custom material handling systems — and we would like to help you optimize yours. Contact us today to discuss what a custom slider bed transfer conveyor could do for you and your material handling and sorting operation. We look forward to working with you.

About Us

For over 40 years Karl Schmidt’s Conveyor’s have provided the recycling industry with top-tier heavy duty conveyors via design, manufacturing and customer service. Now, Karl Schmidt Manufacturing continues the KWS legacy and we pride ourselves in doing what is always right for the customer. One of the most important aspects of having a thriving business is service.

Applications

Regardless if it’s a single slider bed conveyor, a small engineering services project, or a single stream MRF, the Karl Schmidt Mfg.’ outlook remains the same, “Do What is Right For the Customer” regardless of their purchase!

Products

We have been engineering & manufacturing conveyors and related recycling equipment since 1978. We have installed thousands of Conveyors, a variety of dual stream systems and single stream recycling systems all over the United States as well as internationally around the World.